![]()

![]()

Do-It-Yourself information for the modifications I've completed

![]()

Do-It-Yourself information for essential wear and tear items

![]()

Articles covering all the ways to maintain your car

![]()

All about the BMW 330ci

![]()

Various links that I've found valuable

![]()

A few pictures of my car and some others

Changing Your Brakes

Warning!

The information provided at "Bmw330ci.net" web site is "as is" with all faults and without warranty of any kind, expressed or implied, including those of merchantability and fitness for a particular purpose, or arising from a course of dealing, usage or trade practice. "Bmw330ci.net" web site nor it's owner/creator, can not and does not provide any warranty, expressed or implied, about the accuracy or use of information found on "Bmw330ci.net" web site. The user assumes that risk.

THE USE OF THIS INFORMATION IS FOR YOUR REFERENCE ONLY. BMW330CI.NET AND ITS OWNER/CREATOR DISCLAIM ALL LIABILITY FOR DIRECT, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR INJURIES THAT RESULT FROM ANY USE OF THE EXAMPLES, INSTRUCTIONS OR OTHER INFORMATION ON THIS PAGE.

Difficulty

Changing your brakes isn't very challenging at all. It may seem a bit difficult if you have never done it before, but I promise that it's really quite easy. The hardest part is lifting up the car and taking off each wheel. The anti-rattle clips can be confusing at first, but with a big screwdriver, everything will work out. After you've done it once, you'll never take another car in.

Choosing the Right Pads and Rotors

If you've done your research, you'll find a ton of people out there that will tell you different pads or rotors are best (OEM vs. Aftermarket). For my rotors, I picked up a set of BMW's performance rotors which are currently discontinued (I had them in the garage for a couple years). These are two piece floating rotors on the front and are amazing! As far as making a difference, they will help with unsprung weight, but the average driver won't notice any difference. Therefore, I'd recommend a quality blank rotor. As far as pads go, I was looking for the following items: 1. Better than OEM stopping power 2. Lower dusting (not that big of a deal to me) 3.The ability to take the car to the track and use the same pads. Therefore, after reading a lot of reviews I settled on Performance Friction Z-Rated Pads. Once I've driven on them for a while and have made sure they're properly bedded, I'll write up a review on the pads themselves.

Performance Friction Z-Rated Pads |

Performance Rear Rotors |

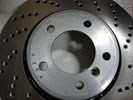

Performance Front Rotor |

Performance Front Rotor Closeup |

Tools Needed

Torque Wrench (20-100 Ft-Lbs)

6mm and 7mm Allen Socket

Various Sockets and Wrenches (17mm)

Flat Head Screwdriver (Bigger the better)

Rubber Mallet (A more powerful hammer may be needed if the rotor gets stuck)

Parts Needed

BMW Performance Cross Drilled Front Rotor x2 (BMW P# 34-11-0-431-905, BMW P# 34-11-0-431-906) $150

BMW Performance Cross Drilled Rear Rotor x2 (BMW P# 34-21-0-431-907) $150

Performance Friction Z-Rated Front Pads (P# 394) $100

Performance Friction Z-Rated Rear Pads (P# 548) $105

Brake Cleaner & Anti-Squeal Compound (Can be picked up at any auto parts store)

PB Blast or equivalent to help remove siezed rotors

Anti-Sieze Compound (To make the job easier next time)

Instructions

Safely lift the car

1. Using a lift or a floor jack with ramps lift at least the front of the vehicle. Instructions for jacking up your car can be found here. This can be a very dangerous step, so make sure that the car is properly secured before ever getting under it. Never get under a car that is just supported by a jack!

Rear Axle Instructions

Remove the rear wheel  Remove the rear wheel |

Remove the rear wheel |

Remove the anti-rattle clip |

Remove the Anti-Rattle Clip |

Upper dust cap  Lower Dust Cap  Pry off with screwdriver  Remove guide bolts |

Remove the caliper guide bolts |

Brake pad wear sensor  Everything disconnected |

Disconnect the brake pad wear sensor (only on the rear passenger side) |

Remove pads from caliper  Brake pad sensor  Make sure the caliper is supported |

Remove the caliper and brake pads |

Remove bolts holding the support bracket  Caliper support bracket removed  Remove rotor set screw  May be needed to help remove the rotor |

Remove the caliper support bracket and brake rotor |

My products in the garage  New brake pads  Spray some anti-squeal on the rear of the pads and on bracket  Reinstall the pad and sensor if applicable |

Clean, lubricate, and install new pads |

Everything put together  Another shot  Finished look  Finished look |

Reassemble everything |

Front Axle Instructions

Remove the front wheel  Remove the front wheel |

Remove the front wheel |

Remove the anti-rattle clip |

Remove the Anti-Rattle Clip |

Upper dust cap  Remove guide bolt |

Remove the caliper guide bolts |

Sensor line  Everything disconnected |

Disconnect the brake pad wear sensor (only on the front drivers side) |

Remove pads from caliper  Make sure the caliper is supported |

Remove the caliper and brake pads |

Remove bolts holding the support bracket  Remove rotor set screw  Clean up the hub |

Remove the caliper support bracket and brake rotor |

My products in the garage  Caliper carriers  Spray some anti-squeal on the support bracket where the pads sit  New pads  New pads coated in anti-squeal  Pad wear sensor replaced |

Clean, lubricate, and install new pads |

Put the pad on the carrier first  Then put the caliper onto the new rotor  Finished look  Finished look |

Reassemble everything |

Brake Bedding Procedure

I can't stress how important it is to properly bed your brakes. This will put a small film of the pad onto the rotor to improve performance all around. I've added a link by Dave Zeckhausen who explains it better than I can, so please take a look and follow the directions: http://www.zeckhausen.com/bedding_in_brakes.htm

Conclusions

WARNING: When you first use your brakes, you may have to push the pedal a few times to get them to firm up, this is normal since we pushed the piston all the way back into the caliper. Remember that at first your car will not stop like it has been due to the coating on the rotors and the fresh pads. Make sure that you are cautious as you take her out for the first spin. Take it easy and after you've driven a bit to let all of the protective coating to be worn off the rotors, bed the brakes properly in order to have them operate as they were designed.

This is a simple do-it-yourself job and you should be proud of yourself for saving a couple hundred bucks. I hope you took some of that money and invested it well into some quality pads and rotors. Remember that brakes and tires will most likely safe your life, so don't go cheap. Happy motoring!

Disclaimer

All product manufacturer logos are property of their respective manufacturer.